Briquetting of materials, production residues, and waste

Address

MVE – ENERGO, s. r. o.Priemyselná 1/4412

031 01 Liptovský Mikuláš

IČO: 36 806 544

https://mve-energo.sk/

Contact person

Matúš Hajdu0919 132 628

matus.hajdu@mve-energo.sk

View profile

Description

Briquetting is a process actively supported and implemented by MVE-ENERGO, s.r.o. It involves transforming unused residual materials, such as industrial sludge, into suitable energy carriers in the form of briquettes. This process is important not only for the efficient use of waste materials but also for reducing environmental impact.

MVE-ENERGO offers a wide range of services in the field of briquetting, including the sale, installation, and service of hydraulic briquetting presses. The company is the exclusive partner of the German manufacturer RUF, known for its high-quality briquetting presses. These presses are capable of processing various types of sludge, which may contain process liquids such as emulsions or oils, thereby achieving high efficiency and cost-effectiveness in briquetting.

Briquetting contributes to better utilization of materials that would otherwise end up as waste, thus supporting sustainability and environmental responsibility in the industry.

Economic benefits

The use of a briquetting press brings economic benefits not only in the form of direct savings, but also increases the value and sustainability of the business in the long term. Briquetting materials and waste in production brings several economic benefits:

1. Reduction of waste costs: briquetting allows to reduce the volume and weight of waste, thus reducing waste removal and storage costs, which can lead to significant savings.

2. Briquettes can be sold as an alternative fuel, providing an additional source of income. Briquettes have a high energy value and are in demand in various industries as a source of heat or energy.

3. By using a briquetting press, the company can efficiently process and recycle waste on-site, reducing the time and logistics required to handle the waste.

4. Environmental subsidies and savings: In some cases, companies can receive government subsidies or tax credits for investing in green technologies and for reducing their environmental impact. Briquetting can help a company meet environmental standards and targets.

5. Implementing sustainable practices such as briquetting can improve a company's public image as a responsible and environmentally conscious business.

6. Briquetting enables companies to better address waste accumulation problems in their operations, ensuring more efficient use of space and equipment.

Environmental benefits

Briquetting offers significant environmental benefits that not only help reduce waste but also improve the overall sustainability of industrial processes. The main environmental benefits of briquetting include:

1. Waste reduction: Briquetting compresses waste materials such as sawdust, chips, sludge and other biomass wastes into a compact form. This significantly reduces the volume of waste, making it easier to store and transport.

2. Recycling of materials. These materials can be reused as raw materials in a variety of industrial applications.

3. The use of briquettes as an alternative to fossil fuels can lead to a reduction in carbon emissions. Briquettes have a lower carbon footprint than traditional coal or wood fuels and burn cleaner with fewer emissions.

Energy efficiency: briquettes have a high energy value, which means they generate more heat when burned, leading to higher efficiency compared to untreated waste materials.

5. Improved waste treatment: Briquetting makes waste easier to handle and also makes it more manageable within existing waste treatment systems.

6. Promoting sustainable practices: the use of briquetting presses can help companies achieve their environmental goals, which can lead to better compliance with environmental regulations and standards.

These environmental benefits of briquetting make the process an attractive option for many industries looking for ways to improve their environmental footprint while increasing the efficiency of their operations.

Examples of implementation of the solution in practice

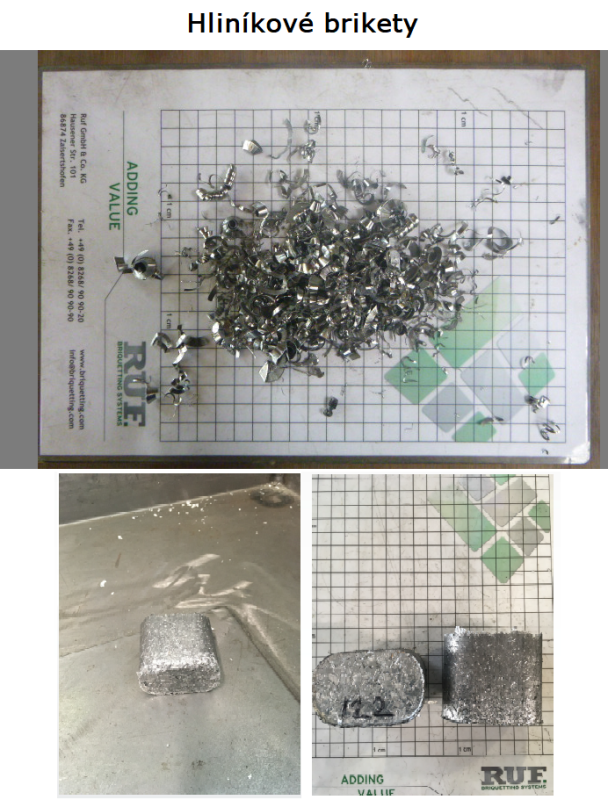

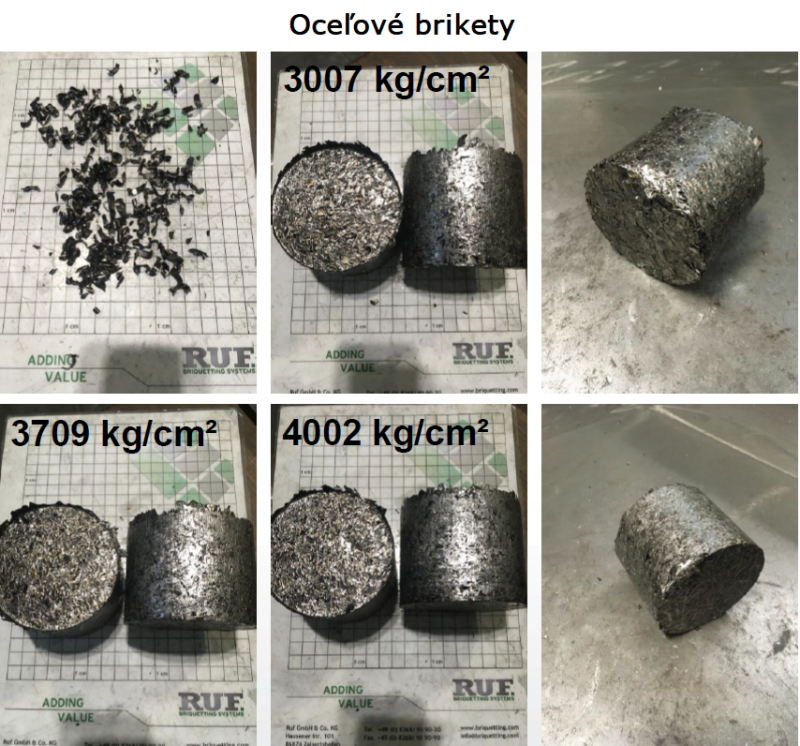

- briquetting of clay shavings and chips

- briquetting of brass shavings and chips

- briquetting of steel shavings and chips

- briquetting of sawdust and wood chips as well as dust

- briquetting of various other organic and inorganic materials