Recycling Equipment for Contaminated Solvents – TECHNIKUM

Address

TECHNIKUM s.r.o.Coburgova 13

917 02 Trnava

IČO: 36 291 994

www.technikum.sk

Contact person

Patrik Pocisk+421 905 855 000

pocisk@technikum.sk

View profile

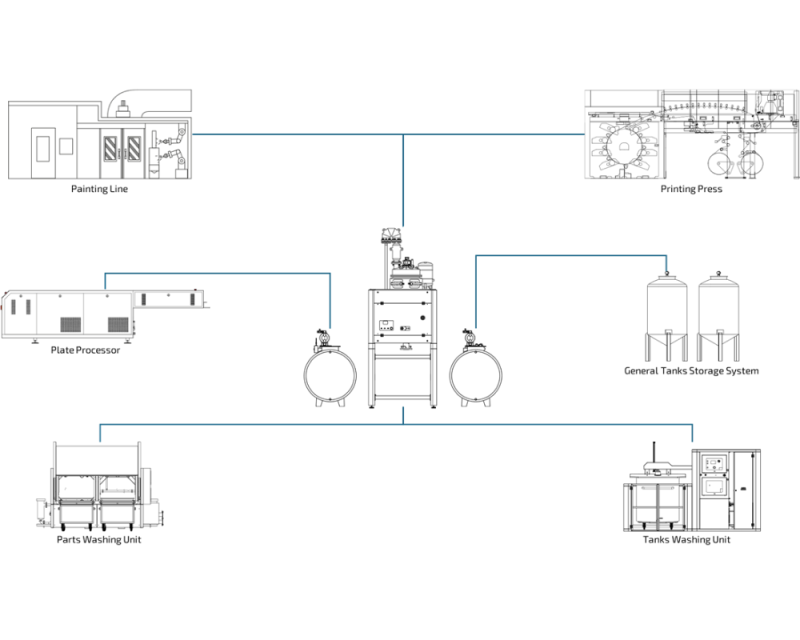

Description

TECHNIKUM s.r.o. provides advanced recycling equipment for contaminated solvents using vacuum distillation technology. These systems allow up to 90% recovery of used solvents, significantly reducing waste and the need for new chemicals. In collaboration with I.S.T. Italia Sistemi Tecnologici S.p.A., we offer solutions with a distillation capacity ranging from 200 to 550 liters per hour, tailored for industrial facilities seeking sustainable and cost-efficient alternatives. Our technology is highly efficient, automated, and environmentally friendly, supporting the principles of circular economy and resource sustainability.

Economic benefits

By recycling solvents, we significantly reduce the costs associated with hazardous waste disposal and the purchase of new chemicals. Efficient use of existing resources allows companies to reduce operating costs by up to 70%. Long equipment life and low operating costs bring a rapid return on investment. Process automation saves labour and increases productivity.

Environmental benefits

Naše zariadenia prispievajú k minimalizácii odpadu a znižovaniu uhlíkovej stopy. Regenerácia rozpúšťadiel eliminuje potrebu ich spaľovania alebo ukladania na skládky, čím sa predchádza znečisťovaniu pôdy, vody a ovzdušia. Vákuová destilácia umožňuje efektívne využitie chemikálií a podporuje princípy obehového hospodárstva, čím prispieva k ochrane životného prostredia a udržateľnosti priemyselnej výroby.

Examples of implementation of the solution in practice

Our recycling equipment has been successfully implemented in several industries, including automotive, chemical and mechanical engineering. For example, at a company specialising in coatings, we have been able to recover up to 85% of used solvent, saving more than €50,000 per year in new chemical costs. Another example is a company in the metal painting sector, where the implementation of our technology has led to an 80% reduction in waste production and the achievement of a higher environmental certification.