Ice surface preparation and operation of ice rinks

Address

ABC Food Machinery spol. s r.o.Nerudova 51

821 04 BRATISLAVA 2

IČO: 31 346 871

https://abcfood.sk/

Contact person

Juraj Grieš0911 517 529

info@abcfood.sk

View profile

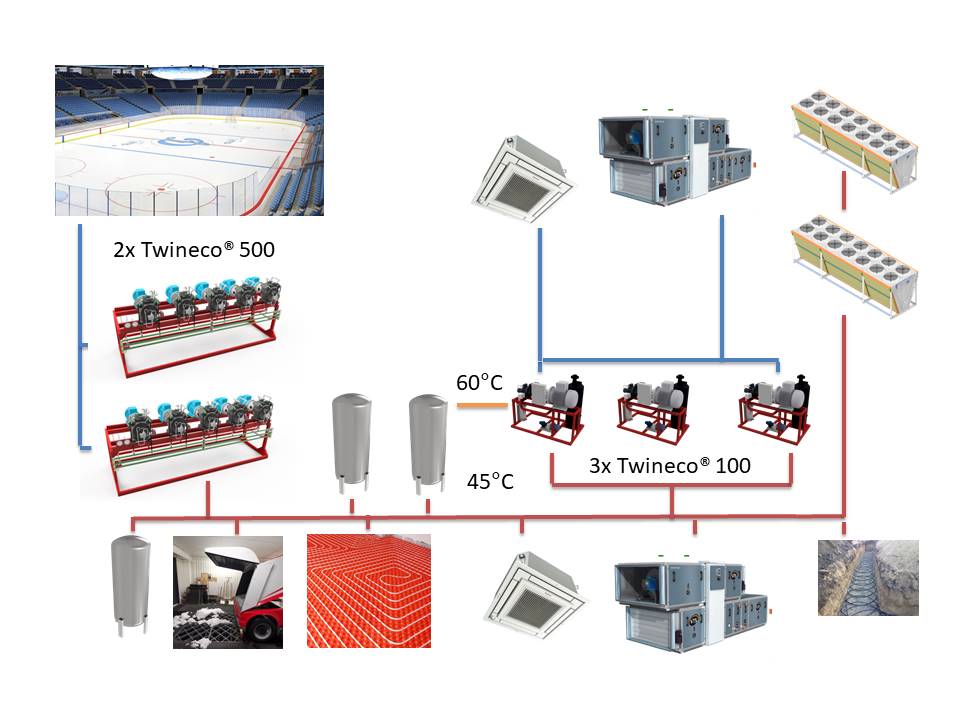

Description

When designing the technology for an ice rink, it is necessary to determine the most accurate operating conditions to ensure that the equipment operates optimally and as efficiently as possible under all conditions. At the same time, there is also the need for heat for heating, domestic hot water, etc. Based on the calculation of these needs, the maximum and minimum cooling and heat output is determined and the most suitable heat pump is selected. The maximum demand is determined by the ice production at the beginning of the season and is several times higher than the cooling demand for subsequent operation. By spreading the power among a larger number of smaller compressors as opposed to one large compressor, the instantaneous power needs can be covered efficiently. It reflects both maximum and minimum cooling and heating needs throughout operation, as well as a back-up in case of service. The technology with one large compressor is not able to cover the same power range of cooling and heating needs as the company's technology, as the compressor design does not allow it. The next step is to choose the right refrigerant, which is 100% environmentally friendly, natural R717, its high volumetric refrigerant capacity allows the use of a minimum charge volume, which has a major impact on several economic and environmental indicators.

Economic benefits

- significantly lower energy consumption,

- the use of all the "waste" heat generated in the production of the cold covers up to 80% of the daily demand (space heating, hot water preparation for the changing rooms and the roller shutter, melting of the ice chips, heating for the air handling units),

- the recycling of water from the ice chips allows water savings of up to 80%,

- significantly improved operating cost efficiency,

- prolonged equipment lifetime,

- simpler and more economical servicing with minimal impact on production and operational continuity,

- increased safety of the plant against possible damage to the environment or to the health of persons,

- a wider possibility of disconnection from fossil fuel supply and greater energy independence.

Environmental benefits

- the use of 100% environmentally friendly natural refrigerants R717 and R723, which do not produce CO2 emissions, have no impact on ODP (Ozone Depletion Potential) and a negligible impact on GWP (Global Warming Potential, the greenhouse effect),

- substantial reduction of the energy consumption of the whole system without the need for gas with minimal electricity consumption, - the integration of heat pumps into the system gives great possibilities for the use of renewable energy sources.

Examples of implementation of the solution in practice

Ice hockey stadiums, ice surfaces, artificial ice climbing walls, ice towers, ice runways, artificial ski slopes.